Fuel Borne Catalyst additive (FBC) is a compound that mixed with the fuel at the tank of vehicles equipped with particulate filter, enables the elimination of more than 98 % of the solid particle matter emitted by this type of engines to the atmosphere, including ultra-fines which are considered to have the most adverse health effects.

The role of the additive is:

Cérine is an organic product and therefore is submitted to degradation in contact with natural light and ambient air.

Once the bottle or can of Cérine is opened, the product will get in contact with oxygen and local ambient air characteristics (moisture, dust...), accelerating the degradation that will significantly affect the final characteristics of the Cérine product.

For that reason, Walker recommends only the use of new sealed Cérine cans or bottles during refilling procedures of vehicles equipped with those additives.

Kept in its genuine Walker packaging, the Cérine fuel borne catalyst additives has a life time of 5 years, that is printed on each can or bottle packaging of the Cérine product.

WALKER DPF REGENERATION ADDITIVE is a combustion catalyst additive that optimizes the regeneration of diesel particle filters for diesel engine (DPF). Diesel engines (FAP). Thanks to its organometallic formula and its post-combustion action, this new generation additive reduces the combustion temperature of carbon soot and eliminates the particles that accumulate in the systems. WALKER DPF REGENERATION ADDITIVE is an economical product and the ideal alternative to OEM additives.

Advantages :

Instructions for use

A : 1st generation tank B : 2nd generation tank

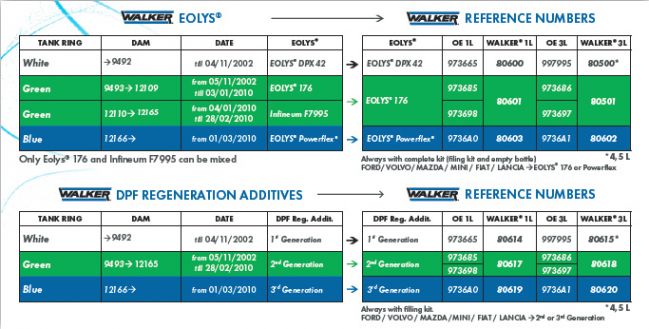

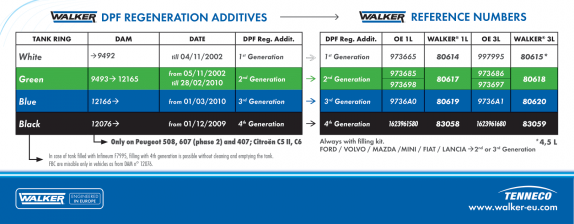

Select the correct additive reference :

Confirm the colour of the snap-on connectors on the additive tank situated at the rear left of the vehicle. Confirm the additive reference according to the APV-PR, OPR or DAM number indicated on the front left door of the vehicle. It is imperative that you do not mix the different references, so follow the connections and compatibility guidelines. Preparation for filling: Wear protective gloves and glasses. Put the vehicle on a hydraulic ramp or above the pit. Disconnect the negative battery terminal and free up the opening to the additive tank situated at the rear of the vehicle, below the left side.

Filling the additive tank :

Download the 1st generation Safety Data Sheets.

Download the 2nd generation Safety Data Sheets.